The cross-sector Innovation Exchange approach was key in facilitating a collaboration between Lucideon and NUVIA UK to solve the issue of hazardous waste encapsulation. Read about this success story.

Radioactively contaminated oil wastes are a common by-product of the nuclear industry and are usually incinerated where the characteristics of the oil allow this disposal route. However, where incineration is difficult to achieve, for a variety of reasons, other disposal treatment solutions are sought. Currently difficult to treat contaminated oils are stored awaiting the development of an appropriate disposal route.

In the pursuit of a sustainable, reliable and long-term solution, NUVIA UK (a major nuclear engineering organisation) decided to launch a challenge through the KTN Innovation Exchange Programme intrigued by its capability to reach more sectors and experts in different fields that would not necessarily come in contact with NUVIA UK and its businesses.

The Process

The challenge was launched in order to find the breakthrough way of dealing with contaminated oils that can’t be incinerated and promoted by Ray Chegwin, who leads KTN’s Nuclear Energy activities. Between others, Lucideon responded with a successful pitch on a relevant concept that could be adapted and implemented for nuclear waste.

Ray Chegwin and NUVIA UK’s Innovation Manager, Adrian Davis-Johnston had previously discussed how the Innovation Exchange Programme could identify technologies from other sectors to complement their current products and services. The ‘Disposal of Contaminated Oils’ challenge was one of four challenges that KTN ran for NUVIA UK and it received several interesting applications, including the ‘winning’ solution from Lucideon.

After presenting its proposed geopolymer solution at a KTN ‘Dragon’s Den’ style event, Lucideon teamed up with NUVIA UK to develop the project.

The need to reduce the amount of stored oil by finding methods of removing particulates that may prevent incineration therefore reducing the stored waste was the original request NUVIA came to IUK KTN Innovation Exchange programme. They were aiming to identify transferable solutions for its innovation and customer needs.

The Outcome

After a successful pitch day in which Lucideon presented its geopolymer solution concept, the two companies started working together on the proposed solution. The project, as per Stuart MacLachlan, Head of R&D at Lucideon

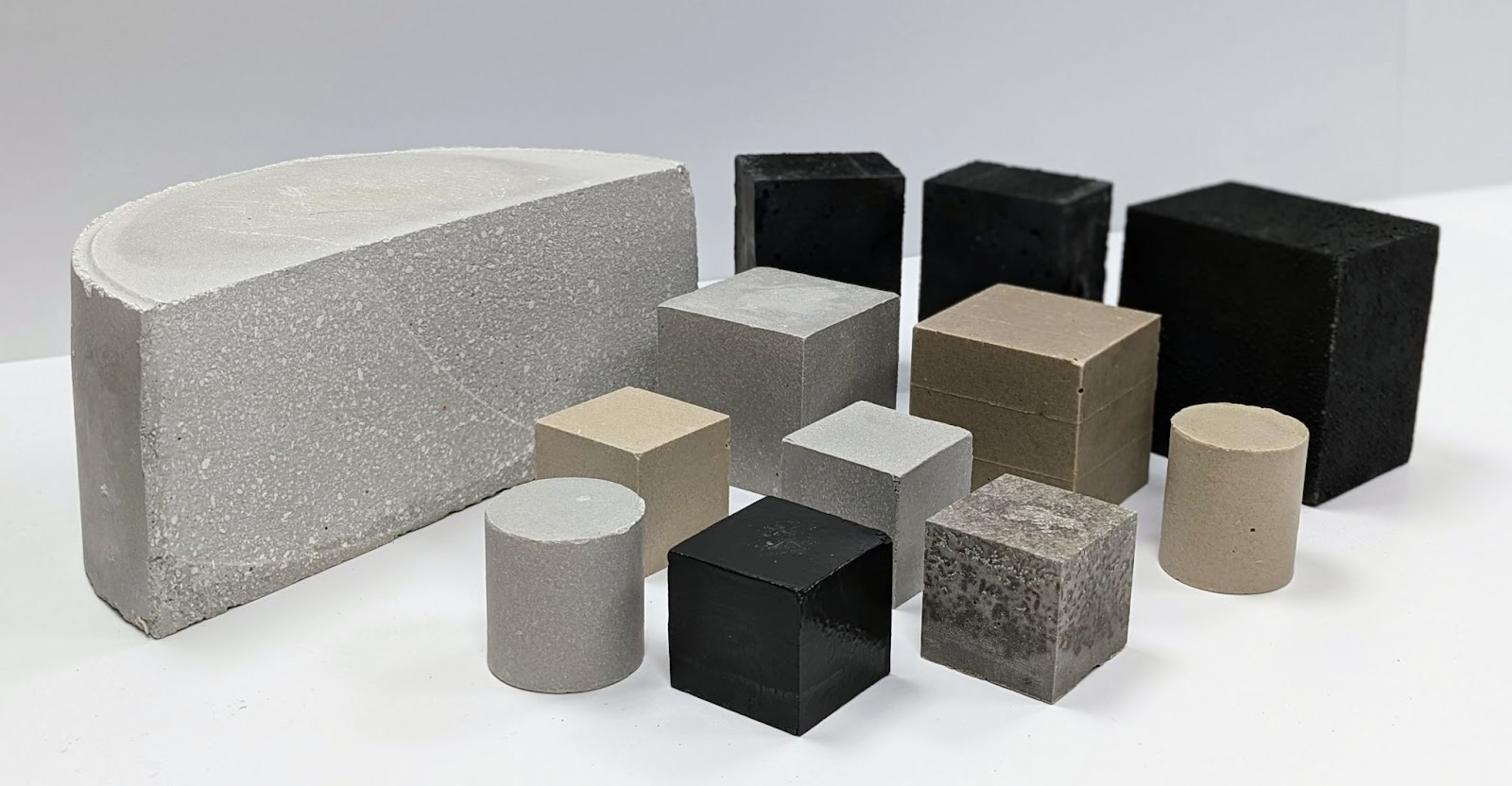

Builds on Lucideon’s work in developing geopolymers tailored for a variety of construction and encapsulation applications. Geopolymer formulations and processes are used to maximise the amount of waste encapsulated, whilst ensuring compliance with disposal requirements.

This innovative solution has opened new routes for the use of cement technology normally applied only in the foundation industries/building sector to create attractive products to manage hazardous waste and represents the first step towards a wider collaboration to create attractive products with low CO2 footprints.

Solution Insight

Together, Lucideon and NUVIA have developed MALLET™ (MIDAR™ Augmented Lower-cost Lower-carbon Encapsulation Technique).

MALLET™ is a new, cost-efficient technique for encapsulating Intermediate Level Waste (ILW) which has the potential to revolutionise nuclear waste disposal. There are no other waste solutions of this type available in the marketplace.

Benefits:

- Significantly lower disposal costs, interim storage costs, and carbon emissions than OPC

- Simple batch process

- Potentially retrofittable to existing encapsulation plant

- Potential ‘pour on solution’ for 3m3 boxes

- Potential to enable near-ground disposal

The aim of MALLET™ is to provide a solution to a global challenge known as problematic nuclear wastes, which are those wastes for which safe, efficient, and cost-effective methods for processing are not readily available. Example problematic wastes include contaminated Sludges, Oils, Zeolites and Graphite. The novel geopolymer formulation will enable nuclear waste owners to process problematic wastes into a passive waste matrix that maximises waste loading and reduces overall waste disposal volumes.

This success story is a tangible example of how IUK KTN and its Innovation Exchange Programme can help in funding innovative solutions, combining cross-sector expertise and supporting the development of new concepts and solutions all the way through, as per Adrian Davis-Johnston, Head of Research, Development and Innovation at NUVIA UK,

We are particularly grateful to Innovate UK KTN who introduced Lucideon to us during one of their pitching sessions. Collaboration is key to solving the issue of hazardous waste encapsulation.