Feedstocks for a sustainable aviation fuel industry

Securing a supply of renewable and sustainable feedstocks is essential to scale the UK sustainable aviation fuel industry, a message high on industry and government agenda.

This week the aviation industry publishes an updated roadmap setting out how it aims to achieve net zero aviation.

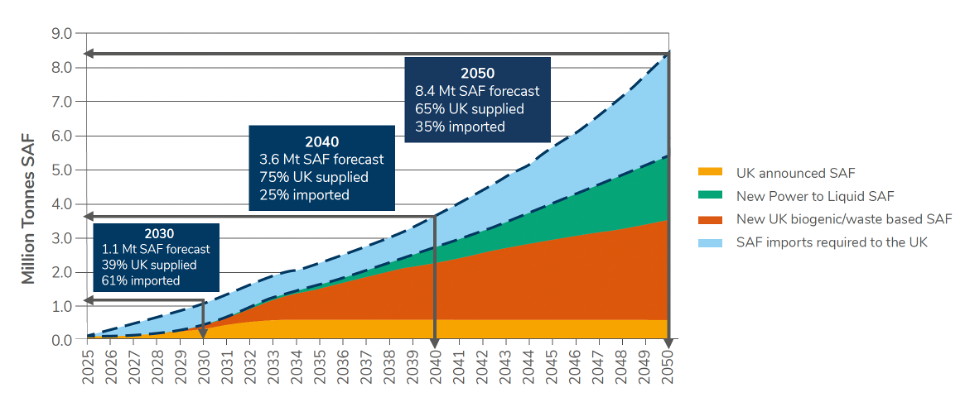

An independent study by ICF conducted on behalf of Sustainable Aviation has identified that the UK could domestically produce 5.4 million tonnes of SAF sourced from sustainable wastes and residues and Power-to-Liquids (PtL) technologies in 2050; providing a CO2 saving of over 17 million tonnes. This represents two thirds of the UK’s anticipated SAF needs in 2050 based on 75% of aviation fuel used in 2050 being SAF.

The publication of the industry roadmap adds to the series of published material to define the path to jet zero, including the government’s Jet Zero Strategy, consultation on a SAF mandate and the two-year plan for UK SAF.

The aim of this short report is to draw out the requirement for sustainably sourced feedstocks to deliver a UK SAF industry; to provide an overview of the key points in the industry roadmap, government policy, recent feedstock analyses and set out the essential criteria for sustainability.

What is sustainable aviation fuel (SAF)?

To be clear on what we are discussing in this short report, we need to be clear on terminology. Aviation fuel is a liquid hydrocarbon required to meet stringent criteria. It must contain certain fit-for-purpose properties and comply with the ASTM D4054 specification. SAF can refer to semi-synthetic aviation fuel (a jet fuel containing a synthetic blend component and conventional jet fuel). A synthetic blend component (SBC) is a synthesised hydrocarbon that meets the requirements in any one of the annexes of ASTM D7566 and is then blended with conventional jet fuel (EI 1533). Not all SBCs are sustainable.

In this short report we refer to sustainable aviation fuel (SAF) as a blend of a sustainable synthetic blend component and conventional jet fuel. Sustainability is an essential criterion for the UK aviation industry and in UK government policy.

By 2020, over 250,000 flights had taken off using SAF blends and over 6 billion litres of airline offtakes had been achieved. SAF only accounts for 0,01% of current global jet fuel use, but with the right support, it is expected to reach up to 2% by 2025 (RSB).

Sustainability criteria of SAF

The Roundtable for Sustainable Biomaterial (RSB) is a global membership organisation that drives the just and sustainable transition to a bio-based and circular economy. RSB has a unique decision-making structure based on consensus among all relevant stakeholders and their Principles & Criteria are recognised as best-in-class in addressing key sustainability issues in a comprehensive way. The RSB Principles & Criteria are based on a management and risk-oriented approach. Together with their online tools and related guidance documents, the RSB Principles & Criteria help operators to identify and manage sustainability issues in a specific context and therefore reduce risks for operators, brand owners and investors.

RSB’s ICAO Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) Standard specifies requirements for operators along the SAF supply chain to produce SAF that complies with RSB’s sustainability requirements and is eligible under CORSIA. RSB’s best-in-class certification system will work to support the implementation of CORSIA for the aviation industry as a recognised Sustainability Certification System. The RSB approach enables committed airlines to go above and beyond the CORSIA requirements in ensuring that the development of SAF and the planet and achieves a minimum of 50% GHG reduction on a lifecycle basis (RSB).

When considering suitable SAF offtakes with suppliers, airlines will assess the fuel to fully understand its sustainability credentials and whether it is RSB certified.

Sustainable Aviation highlights the key sustainability criteria for SAF in the graphic below (this aligns with the RSB criteria).

Feedstocks for aviation fuel

The Royal Society recently published a report on the range of fuel types for aviation includes a few possible options suitable to develop SAF (liquid hydrocarbons). It included a comprehensive analysis on the availability of some feedstock types. Used cooking oil in the UK can be utilised to provide 0.3 to 0.6% of the total amount of jet fuel required every year in the UK. The report also calculated that to meet the 12.3 million tonnes of jet fuel per year will require 42.4 million tonnes of rapeseed biomass per year and 68% of UK’s agricultural land. The report suggests that utilising Miscanthus for alcohol-to-jet in the UK will require 10.3 to 6.2 million hectares to meet UK fuel demand.

The roadmap published this week by Sustainable Aviation clearly states that the industry will only fly on SAF utilising feedstocks that meet strict sustainability criteria. This includes not flying on fuel derived from feedstock grown on agricultural land destined for food crops.

ICF were commissioned by Sustainable Aviation to conduct an analysis on the feedstock availability and SAF production potential to deliver a UK SAF industry. The analysis shows that the availability of sufficient feedstock is not a limiting factor in building a UK SAF industry. As sustainability is an essential criterion, feedstocks likely to compete with food production were excluded from their analysis. Not included in the Royal Society report but considered in the ICF analysis is recycled carbon as a route to UK SAF production. There are projects currently under development in the UK utlising waste industrial gasses, used tyres and plastics to generate SAF. The UK government is currently assessing the viability and scope of supporting renewable carbon fuels under the Renewable Transport Fuel Obligation.

The UK aviation industry is committed to flying on a SAF derived from wastes and residues. This can include agricultural waste, municipal waste (black bin waste), wood residues, waste industrial gases, sewage sludge, algae and cover crops. The challenge for the aviation industry is that other sectors are competing for the same feedstocks and various studies indicate that between 14 and 30% of wastes and residue feedstocks will be available for aviation (ICF, 2023).

Both the Royal Society report and Sustainable Aviation roadmap reference sewage as a potential feedstock and route to a sustainable jet fuel. Approximately 1.5 MT of sewage sludge is produced in the UK each year offering a 10-15 MJ/Kg energy content. Overcoming challenges around unlocking current long-term energy contracts for fertiliser provision and the high temperatures required to process the sewage, can offer a sustainable route to meeting UK’s aviation fuel demand (ICF, 2023).

The ICF analysis on feedstocks for the Sustainable Aviation Roadmap concludes by highlighting the need for development of technologies to unlock the processing of novel feedstocks and securing longer-term supplies of dedicated feedstocks. These are also themes to emerge from the Jet Zero Council SAF Delivery Group and will be a priority area for the next two years for the SAF Delivery Group.

UK government policy on SAF

The UK government is committed to delivering a UK SAF industry and has recently launched the second consultation for a SAF mandate which aims to generate a long-term supply and incentivise suppliers through tradeable certificates. Fuels offering higher GHG savings will receive greater support through the scheme.

The consultation considers the implementation of a Power-to-Liquid (PtL) sub-target in the mandate. Whilst this route does not rely on feedstocks, it does require energy to make hydrogen and capture carbon (where relevant). The UK Government recently amended the Energy Act (2004) to enable the support of recycled carbon fuels (RCFs) and nuclear derived fuels (NDFs) under renewable transport fuel schemes. Currently powers only permit renewable fuels to be supported. However new fuels, such as RCFs and NDFs are critical to production of SAF and hydrogen and should be able to be supported under the same frameworks.

Hydroprocessed esters and fatty acids (HEFA) is the most common process for producing SAF globally and is an approved Annex in ASTM D7566. In some nations, the feedstock for this process is oilseed rape or palm oil. The UK currently uses waste oils and fats to make biodiesel and even as the road sector transitions to electric, there will not be sufficient waste oil and fats to contribute significantly to domestic SAF production. As such, the government is seeking evidence to impose a HEFA cap on UK suppliers and incentivise the development of new technologies and feedstocks. If you have evidence and views to inform this decision, please do input into the consultation process.

The proposed mandate will incentivise fuels with a carbon intensity of at least 40% relative to fossil kerosene. Eligible fuels under the proposed mandate will include biofuels derived from wastes and residues, RCF’s and PtL. Food, feed and energy crops are excluded.

Further to assuring sustainability, biofuels derived from agricultural wastes and residues will be subject to land and soil carbon criteria. Biofuels derived from forestry wastes and residues will be subject to forestry criteria. The criteria can be viewed in the RTFO and is aimed at ensuring any land use impacts resulting from harvesting of the principle crop and/or collection of any waste are appropriately managed (p50 SAF mandate consultation).

UK SAF production potential

The Sustainable Aviation Roadmap estimates that 1.1 million tonnes of SAF will be required in 2030 to meet the UK government’s target of 10% SAF in UK’s aviation fuel mix, of which 0.4 million tonnes could be delivered through UK production and the remainder would be met by imports. Based on a 75% mandate level by 2050 this would increase to 8.4 million tonnes of SAF, of which 5.4 million tonnes could be delivered through UK production and the remainder would be met by imports (see below figure from ICF as part of the fuels analysis in the SA Roadmap).

SA’s Roadmap also reveals that in 2030, UK SAF production would create over 10,300 jobs and generate nearly £1.8bn of GVA rising to £10bn in 2050. The analysis within the roadmap highlights the need for more than the five committed SAF production facilities in construction by 2025 indicated in the Jet Zero Strategy.

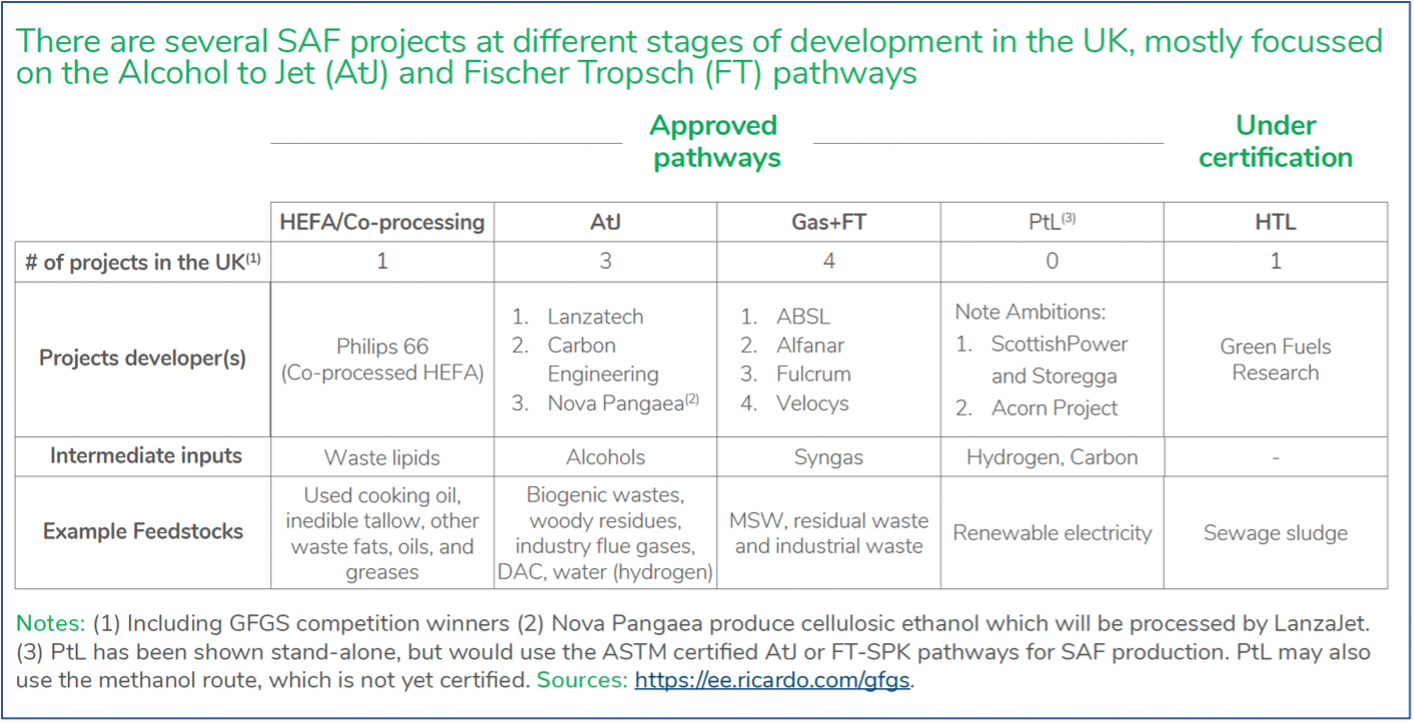

The table below is taken from SA’s Roadmap and highlights the SAF plants either in production or in various stages of development. All projects utilise a waste stream as feedstock (except the PtL projects) reinforcing the commercial reality of selecting feedstocks which meet the stringent sustainability criteria airlines seek and align with UK government policy.

Conclusions

Whilst the air worthiness and technical specification of any new fuel is the primary criteria for ASTM approval, the sustainability credentials of the fuel will need to be assessed through organisations offering that service and can be certified through the RSB. Airlines will assess both of these elements in any new fuel alongside the emission reduction potential. Wastes (biological or gas), residues, renewable carbon or Power-to-Liquids will be the main feedstocks generating a UK SAF industry, at least considered favourable to the industry and eligible under the new SAF mandate. The Sustainable Aviation’s Roadmap sets out how the industry will decarbonise to 2050 through a range of interventions including airspace modernisation, carbon removals, hydrogen and electric propulsion plus SAF.

The Jet Zero Council SAF Delivery Group has published its two-year plan this week, highlighting the main priority areas members will work towards:

- SAF mandate in legislation by 2025

- Five plants in construction by 2025

- Exploring options to commercialise SAF alongside a SAF mandate

- Securing long-term supply of feedstocks and unlocking novel feedstock options

- Understanding the non-CO2 impacts of SAF in use

- Carbon removal options

- Raising the SAF blend to 100%

A common theme to emerge from the government’s SAF mandate consultation document and the Sustainable Aviation Roadmap is the need for the UK to unlock more technology and sustainable feedstock options. This will offer a portfolio of production options and help scale the industry to meet the 10% SAF in the UK aviation fuel mix by 2030 target.

More information about SAF

Related programme

Sustainable Aviation Fuel Innovation Programme

Accelerating the development of UK’s SAF industry and enabling UK Government to achieve 10% SAF in the UK jet fuel mix by 2030. By fostering innovation and collaboration across industry, the SAF IP is building the supply chain, enabling new fuel development and demystifying the SAF landscape.