Industrial Gases to Chemicals: Collaborating to transform foundation industries towards circularity

The Innovate UK Transforming Foundation Industries (TFI) challenge was set up to enable the Cement, Ceramics, Chemicals, Glass, Metals and Paper sectors to improve their productivity and competitiveness. By forming new collaborations across the foundation industries, the TFI challenge has been accelerating innovations that can lead to step changes in resource and energy efficiencies in these capital-intensive industries.

With the foundation industries being worth an estimated £45bn to the UK economy, these sectors are the largest polluters, generating 10% of all UK carbon dioxide (CO2) emissions. The chemical sector itself is responsible for an estimated 9.4 MtCO2e of direct UK greenhouse emissions in 2018(1) and in 2020 had an estimated turnover of £32bn and a GVA of £11bn(2). Given its size and its contribution to emissions, the UK chemicals sector has a pivotal role in achieving net zero and a circular economy. It needs to continually innovate to make step changes to become more sustainable, globally resilient, and competitive, with key opportunities existing in the areas of waste valorisation, the use of alternative feedstocks, low-grade heat recovery and industrial symbiosis.

However, for the chemicals sector, forming collaborations with other foundation industries was never going to be easy. An earlier FAQ on ‘What does the Transforming Foundation Industries (TFI) Challenge mean for the Chemical Sector’ highlighted some of the complications the sector faced in understanding how the benefits of the TFI challenge and its competitions could be leveraged. Yet through the TFI challenge the chemicals sector has found ways to work together across the foundation industries and have shown the benefits of this collaborative working.

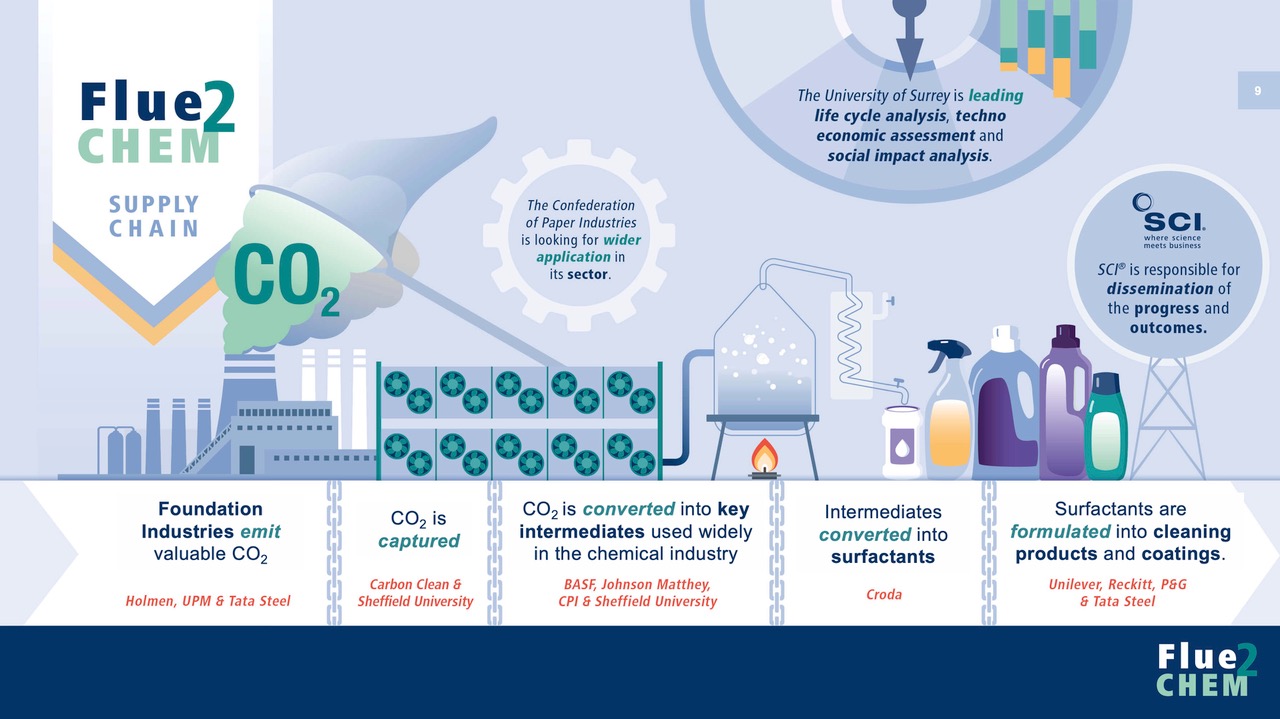

A recent example of a key project funded through the Innovate UK TFI demonstration competition is the Flue2Chem project aimed at redesigning and validating a UK value chain to convert industrial waste gases (both fossil and non-fossil) into sustainable materials for consumer products. The project consists of a consortium of 15 organisations including Unilever, SCI, Tata Steel, UPM, Holmen and other businesses, universities, and non-governmental organisations {see the infographic below}. Flue2Chem is an excellent example of the type of project funded and shows how through Carbon Capture and Utilisation (CCU) of industrial waste gases, the chemical sector could produce higher-value, lower carbon footprint chemicals and reduce its reliance on fossil fuel feedstocks.

Carbon is the backbone of most chemical products, and the Renewable Carbon Initiative estimated that two thirds of the carbon footprint of most chemicals and chemical intermediates comes from the carbon that is required to form the necessary molecules(3). Furthermore, in 2020, the same initiative estimated that the global demand for the carbon used in organic chemicals and their derived materials was 450 Mt/year and predicted this would increase to 1,000 Mt/year by 2050(4). For these reasons, using industrial waste gases as an alternative feedstock to manufacture chemicals is important for the sector, as it can help meet our demand for carbon and lower scope 1, 2 and 3 emissions across the supply chain.

To further support and accelerate work in this area, the Innovate UK KTN Circular Economy Innovation Network has established the ‘transforming industrial waste gases to chemicals’ challenge to develop a community action plan that supports a circular carbon future and to achieve Net Zero through circular innovation.

The action plan aims to develop a clear and consistent message that demonstrates the importance of creating a circular, sustainable, and net zero chemical sector by adopting a Circular Economy framework for Circular Design, Circular Business Models, and Circular Recovery. Following consultation with the wider community, three key challenges have been identified for industrial clusters and dispersed sites and are now seeking partners to work collaboratively to:

- Investigate and generate new circular and sustainable business models across supply chains that should establish the economic, environmental, and social case for manufacturing in the UK.

- Determine the economic, technical, and environmental capabilities of existing and emerging carbon capture and chemical transformation technologies to drive increased investment in collaborative projects.

- Create a policy, regulatory and standards environment that drives behavioural change and to make long term investment attractive.

Next Steps

With a growing population increasing demands on energy systems, raw materials, and supply chains we need to do more to reduce our reliance on fossil feedstocks. The activities of the TFI challenge and other Innovate UK programmes have provided the chemical sector with fantastic opportunities to accelerate innovation in areas that will help defossilisation, and as a sector, we need to embrace more of these opportunities when they arise. Often it can be tricky to understand the scope and relevance of funding calls and it can be challenging to find partners; this is where Innovate UK KTN is here to help you navigate through the funding available and to help connect you to potential partners.

The Circular Economy Innovation Network will also continue to champion the move towards a circular carbon future and the delivery of the transforming industrial waste gases to chemicals action plan by the community.

If you are interested to learn more about future opportunities and to get involved with TFI, the Circular Economy Innovation Network and the Transforming Industrial Waste Gases to Chemicals challenge, please contact our expert Michael Burnett.

By Michael Burnett, Knowledge Transfer Manager – Process Manufacturing

References:

(1) Climate Change Committee. (2020, Dec). The Sixth Carbon Budget: Manufacturing and construction. Retrieved from Climate Change Committee: https://www.theccc.org.uk/publication/sixth-carbon-budget/

(2) Office for National Statistics. (2022, June 16). Non-financial business economy, UK: Sections A to S. Retrieved Jan 2023, from Office for National Statistics: https://www.ons.gov.uk/businessindustryandtrade/business/businessservices/datasets/uknonfinancialbusinesseconomyannualbusinesssurveysectionsas

(3) Kähler, F. and Carus, M. et al. 2022: CO2 Reduction Potential of the Chemical Industry Through CCU. Editor: Renewable Carbon Initiative (RCI), April 2022. Available at:www.renewable-carbon-initiative.com

(4) vom Berg, C. and Carus, M. et al. 2022: Renewable Carbon as a Guiding Principle for Sustainable Carbon Cycles. Editor: Renewable Carbon Initiative (RCI), Febr. 2022. Available at: www.renewable-carbon-initiative.com

Related programme

Circular Economy Innovation Network

The Circular Economy Innovation Network aimed to enable stronger, more resilient industries working together, connecting, collaborating, and sharing experiences to achieve Net Zero through circular innovation.