Enhancing Airtightness Quantification with the Portascanner AIRTIGHT

Developing, verifying, and optimising a rapid, low-cost technology for locating and quantifying air leakage in the built environment.

Project

Enhancing Airtightness Quantification with the Portascanner AIRTIGHT

Lead Organisation

Coltraco Limited

URL

coltraco.com/coltraco-ultrasonics-granted-research-award-for-the-portascanner-airtight/

Location

Durham

Funding

£106,386 (£64,000 Coltraco, £42,384 LBU)

About the project

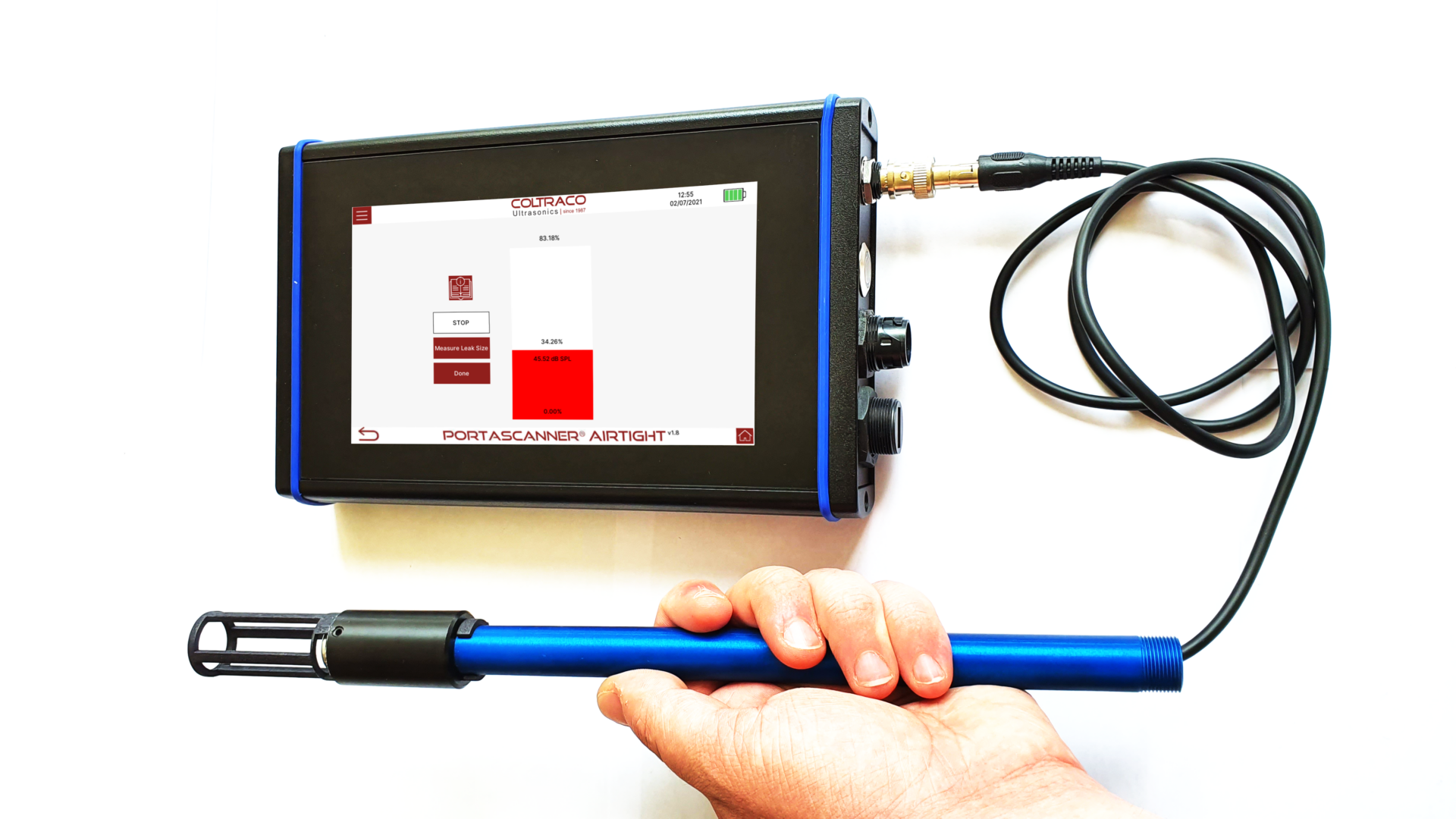

In 2020, Coltraco developed the Portascanner AIRTIGHT, a completely novel instrument originally designed to identify airborne infection routes in the envelope of NHS isolation wards. Its potential quickly became apparent for broader applications in the built environment, particularly for assessing airtightness and thermal performance.

This project aimed to develop a second generation of the instrument, enhancing its usability and practicality while streamlining the supply chain through component reduction. This advancement positions Coltraco to meet the burgeoning global demand for rapid airtightness testing solutions.

Additionally, through an extensive study encompassing both laboratory and real-world testing environments, a compelling body of scientific evidence has been amassed. The results not only offer users reassurance in the instrument’s capabilities but also outlines valuable use cases and guidelines.

Consequently, Coltraco and Leeds Beckett University are collaborating on multiple publications to disseminate their findings.

As Dr David Johnston, Professor of Building Performance Evaluation at Leeds Beckett University, said:

It is important to develop low-cost tools that are capable of rapidly assessing and quantifying the airtightness performance of a building, providing an alternative to existing methods of testing airtightness. All of these tools will be important in helping the UK meet its Net Zero obligations

What has the project successfully delivered?

- The new version of the instrument uses a lighter tablet with enhanced recording of data, an improved camera, and better overall user experience.

- The sensor is now wireless, improving practicality.

- An early version of AI-enabled sensor tracking has been implemented.

- Manufacturing has been simplified and the overall supply chain resilience has been dramatically improved.

- Tests in several environments have been successfully conducted which demonstrate the value and accuracy of the technology.

What has the project achieved?

The project achieved its goals in developing a more refined version of a novel rapid airtightness testing instrument that has the potential to revolutionise the construction of thermally efficient buildings. It involved testing in two different laboratories and on nine different buildings to evaluate the performance of the Portascanner AIRTIGHT alongside blower door tests, PULSE tests, and thermography.

Ultimately, it was discovered that the technology can find air leaks that other methods may miss, can quantify them effectively, and can be used in situations that are impractical for other methods. Thus, the value of the Portascanner AIRTIGHT was successfully demonstrated.

Key lessons learned

- Refining our signal processing was harder than we initially thought, although we were ultimately successful.

- One of the most important advantages of the technology is that it can be used prior to the completion of the envelope. Air leak tests can be conducted before, during, and after the Build Programme.

Next steps

Our next steps are to complete quality assurance and testing of the new product and to begin the launch plan so that the second generation of the Portascanner AIRTIGHT will be available to the market from Q1 2025. We are also in the process of a full write-up of the study and have targeted a conference and an academic journal for paper submission. Finally, we will continue to develop the market for the technology internationally while creating video content and other marketing resources to drive customer interest.