From props to PVC visors: the home-3D printing operation responding to the pandemic

By Alan Cowie

As someone fortunate enough to work from home, I’ve spent a lot of time recently in virtual meetings, but not all my interactions are as inspiring as the 40 minute chat I had with small business owner Andrew Howat. He’s sitting in his lounge at home in Gateshead; the room temperature is a sizzling 30C. Why? Because Andrew’s home is full of 3D printers whirring day and night, and alongside his normal job making 3D printed props for costumes, he has started making protective visors for anyone in his local community that needs them to help stop the spread of coronavirus. “Anyone that tells us that they’re working and they feel they need it, we’re happy to make one for them, free of charge” he says.

It all started when someone posted a message on a local residents group on a social media page, calling for supplies of visors for local GPs and healthcare workers. Andrew was keen to help and after the first batch of 20 visors was printed on his machines at home, more and more calls came in asking if he could help.

“I wanted to help” he said. “There are people out there losing loved ones and we just thought of anything we could do to help.” He adds “It’s not going out there and being a doctor or nurse, but it’s something.” Andrew is modest but you can tell he’s humbled by the overwhelming gratitude he’s received from people in his community, some calling him a hero.

Andrew’s interest in additive manufacturing started when he was training to become a teacher, but he took a different direction when he discovered his passion for 3D printing. “It’s a bit like learning how to ride a bike in that there are basic skills you need to master and get right consistently, or you’ll get a lot of failed prints.”

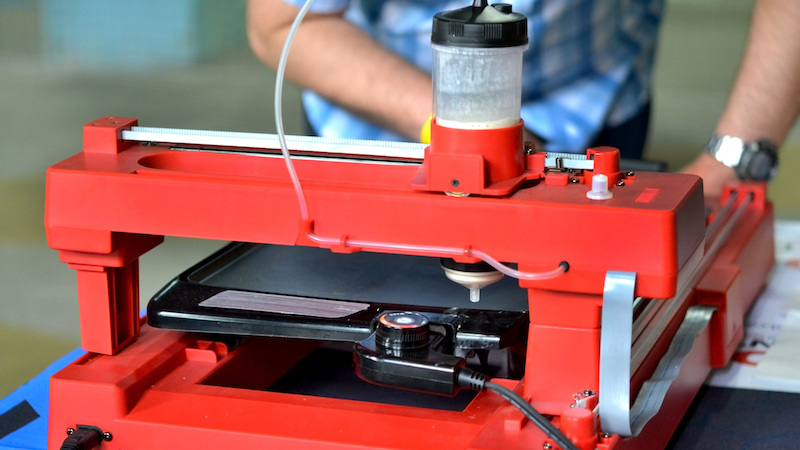

His printers are making the head piece and the clip at the bottom of the transparent visor; the acetate or PVC sheets are then hand cut by Andrew and his wife Kate. The CAD design he’s using was made by the Czech firm Prusa, and it has been signed off by the Czech Ministry of Health. Pharmacies, GP surgeries, physiotherapists and other community-based healthcare workers are amongst those to benefit from Andrew’s contribution. Together, Andrew and Kate have made around 300 visors, which can be sanitised and reused, and he has enough PETG Polyethylene terephthalate and filament to make 700 more. He says he’ll keep going so long as there’s demand.

An interesting twist to this story is that Andrew’s neighbour happens to work for KTN. Catherine Julia Mort, one of our leads on Industrial Biotechnology found out about Andrew’s work on social media and then invited him to a video call to see how she might help. Catherine made a number of useful introductions to experts in additive manufacturing who have given Andrew some advice on sourcing supplies and improving his home operation. I asked Andrew for his top tip for others doing similar grassroots campaigns. He said “Engaging with places like KTN, local makerspaces, or even posting on LinkedIn will give you connections with people that can provide real solutions to your challenges. It’s also about helping to get obstacles out of the way and speed up the process a lot more.”

Catherine said: “It feels good to know you can still facilitate innovation in these times of uncertainty, the sense of unity in my local community during this period of isolation has really lifted our spirits. Where there is a will, there is a way!”

The coronavirus outbreak has really shown the best in people and their generosity, ingenuity and determination to work together to find solutions to difficult challenges. Andrew is a shining example and we recognise and pay tribute to his efforts and to all of you doing your bit, however big or small, to save lives. At KTN, we will continue to do what we do best; using our deep expertise and knowledge to make powerful connections to drive forward positive change.