Funding to build a sustainable future for medicines manufacturing

15 projects have been awarded a share of £1.3m seed funding to support proposals for large-scale Grand Challenges in sustainable medicines manufacturing.

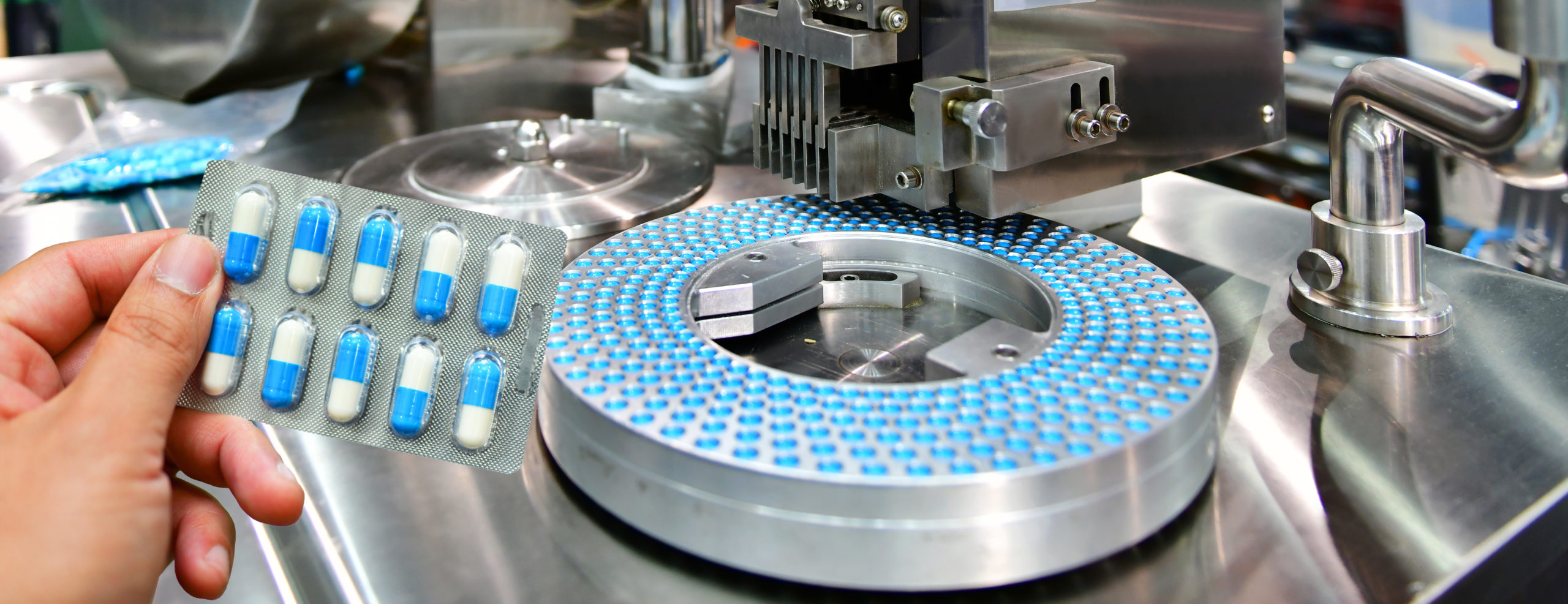

Innovate UK’s Sustainable Medicines Manufacturing Innovation programme (SMMIP) focuses on industry-led innovation towards more sustainable medicines manufacturing in the UK.

In partnership with the Department of Health and Social Care (DHSC), Innovate UK has awarded 15 projects a share of £1.3m seed funding through the SMMIP Expression of Interest competition to support consortium building and the preparation of proposals for large-scale Grand Challenges in sustainable medicines manufacturing.

The successful Grand Challenges will drive industry adoption of significant advancements in sustainable medicines manufacturing innovation.

The SMMIP is funded as part of the wider VPAG Investment Programme agreed as part of the 2024 Voluntary Scheme for Branded Medicines Pricing, Access and Growth (VPAG). The VPAG Investment Programme is a new joint government-industry programme to strengthen the UK’s global competitiveness in health and life sciences and drive innovation-led growth. Enabled by circa £400m of funding from scheme members, it is targeting investment across the UK, with initiatives in three focus areas; clinical trials, health technology assessment, and manufacturing.

Tackling sustainability challenges

Traditional medicine manufacturing processes can be resource-intensive, generating significant waste and greenhouse gas emissions. The challenge lies in reducing waste, energy consumption, and emissions, while simultaneously enhancing efficiency, safety, and cost-effectiveness throughout the manufacturing lifecycle.

By addressing these challenges through innovation and collaboration across the supply chain, the sector can reduce its environmental footprint while driving advancements in manufacturing processes. Embracing innovative approaches will enhance resilience and efficiency, ensuring the industry is well-positioned to meet the growing demands of future healthcare systems whilst aligning with NHS climate change policies and targets.

Expression of interest projects

The funded projects are spread across the UK and align with the three SMMIP pillars:

- Circularity

- Green Chemistry

- Productivity and Resource Efficiency

“Through the SMMIP, we want to support innovation to make medicines in a way that minimises environmental impact, conserves natural resources, and ensures economic and social sustainability. The scale and ambition of these collaborative projects are a testament to the UK’s innovative potential to drive impactful change in this way.” – Dr Sarah Goulding, Director of Future Medicines at Innovate UK

Circularity Pillar

Circularity in Volatile Anaesthetics

Project lead: SageTech Medical Equipment Ltd

The project will deliver a business model and technical processes for an optimised and sustainable waste volatile anaesthetic remanufacturing company scaled for global expansion.

Green processing technology platform for development of high-performance, smart, sustainable packaging

Project lead: National Physical Laboratory

Development of a supercritical CO2 based technology processing platform to increase adoption and promote uptake of sustainable pharmaceutical packaging using green chemistry and sustainable manufacturing processes.

Harvesting the UK’s Radionuclide Assets for Medical Applications

Project lead: United Kingdom National Nuclear Laboratory Ltd

Develop a proposal for extraction and purification of radionuclides suitable for researchers and drug development companies to use for Targeted Alpha Therapy research and development.

Remanufacturing for a Sustainable Future in Combination Injection Devices (ReSCid)

Project lead: Owen Mumford Ltd

We are creating a consortium to build a circular eco-system to transform the

manufacturing of sustainable injection devices.

Green Chemistry pillar

Environmental Peptide Production

Project lead: Origin Peptides Ltd

We are scaling our environmentally friendly peptide synthesis process to make medicines more affordable, available and better for the planet.

Overcoming Technical, Commercial and Regulatory Barriers for Integrating Low-GHG Solvents in Sustainable Medicine Manufacturing Supply Chains

Project lead: Environmental Resources Management Ltd

This EoI project will assemble a supply-chain consortium to identify and overcome barriers to integrating low-GHG solvents for sustainable medicine manufacturing.

Sustainable Seaweed Based Components in Medicines Manufacture

Project lead: Mercel Ltd

This project will build a consortium with seaweed producers, ecologists, technologists and medicine manufacturers to enable sustainable seaweed-based nanocellulose replacements for microplastics in medicines.

Productivity and Resource Efficiency Pillar

A Sustainable Future Factory

Project lead: AstraZeneca UK Ltd

Our vision is to revolutionise pharmaceutical manufacturing by integrating AI-driven robotics and automation for sustainable, efficient, and innovative processes, enhancing precision and reducing waste.

Digital Formulation Design and Manufacture for a Sustainable Pipeline of the Next-Generation of Bioavailable Medicines

Project lead: Mesox Ltd

Medicine formulation before clinical trials is inefficient and wasteful, with poor bioavailability causing failures. Our project integrates advanced digital models to optimise formulation development with focus on Amorphous Solid Dispersions, improve process sustainability, and minimise waste.

DPN-MED: Digital Plug-and-Produce Network for Sustainable Medicines Development and Manufacturing

Project lead: National Manufacturing Institute Scotland

The Grand Challenge aims to transform medicines manufacturing through a distributed network of resource-efficient, self-driving, plug-and-produce technologies integrated in a connected digital infrastructure.

EcoCAR: Sustainable CAR-T cell manufacture

Project lead: Royal Free Hospital

The EcoCAR initiative proposes to reduce the environmental burden associated with manufacturing of CAR T therapies through the development of an all-in-one microfluidics solution.

InSPIREmed – Integrated Spectroscopy and Photonics for Increased productivity and Resource Efficiency in Medicines manufacture

Project lead: Fraunhofer UK Research Ltd

The InSPIREmed project will boost Productivity and Resource Efficiency of medicines manufacturing using advanced photonic sensing to more accurately control processes.

Optimising Energy Efficiency for Sustainable Medicines Manufacturing

Project lead: Decision Lab Ltd

Creating an innovative platform to enhance production efficiency in medicines manufacturing by aligning operations with renewable energy availability, reducing energy consumption, and improving sustainability.

Streamlining the use of biocatalysis for API manufacture through digitisation, AI and machine learning

Project lead: Disyn Biotec Ltd

Build a consortium to develop a digital platform leveraging AI and machine learning to design chemo-biocatalytic routes with sustainability as a central consideration.

Smart, Sustainable RNA-LNP Manufacture

Project lead: Centre for Process Innovation Ltd

Transforming RNA-LNP manufacture and supply by creating sustainable, efficient, flexible processes that cut waste, speed up production, and deliver next-generation medicines with minimal environmental impact.

Related programmes

Transforming Medicines Manufacturing

Innovate UK’s Transforming Medicines Manufacturing programme aims to drive the de-risking and adoption of highly innovative flexible, agile and scalable manufacturing technologies through a culture of collaboration that will drive the growth of this critically important manufacturing sector.

Sustainable Medicines Manufacturing

The Sustainable Medicines Manufacturing Innovation Programme will focus on innovation in sustainable medicines manufacturing to improve the manufacturing innovation ecosystem in the UK towards a sustainable future.