AI takes the heat out of decarbonisation

You hear AI, and let’s be honest, you don’t think of industrial manufacturing. But what if AI could be a critical tool to decarbonise the UK’s foundation industries?

The foundation industries, which include cement and concrete, ceramics, chemicals, glass, paper and metals, each have a huge carbon footprint baked into them to start with. For example, the British cement industry contributes 1.5% of our total annual carbon emissions – that’s approximately 7.3 million tonnes of carbon, every year.

Given that these materials are the literal foundation to our modern world, it is vital that we find ways to produce them more sustainably.

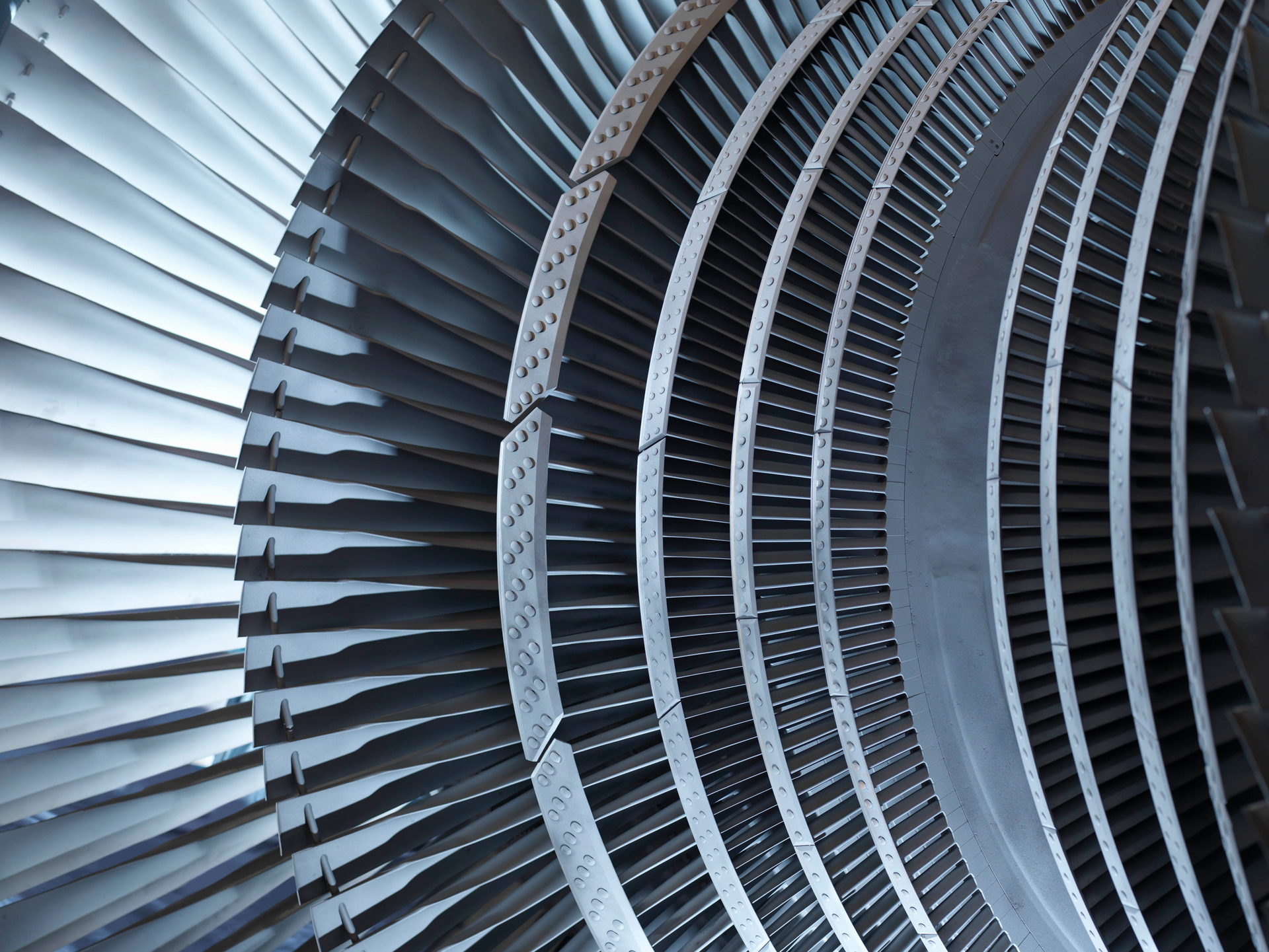

Most of the emissions from the foundation industries come from the fuel required to produce the heat needed in the production process. In cement production, this is called the pyroprocess. Here, high temperatures – 1,460°C to be exact – are required to create the key ingredient of cement, clinker, within a kiln. Electrifying this process is not a practical option, at least currently. Alternative fuels, like hydrogen, can help to reduce emissions but require testing and evaluation.

AI can help

What if there was a way to change how cement is produced in order to cut emissions? Imagine having a helping hand watching the manufacturing process, calculating how things might be done better. Cement production has been honed over decades but as the process becomes increasingly digitised, there are more sophisticated ways to use the data.

Carbon Re spun-out from UCL in 2021 on a mission to drastically reduce industrial carbon emissions. Through support from Innovate UK, Carbon Re has developed and deployed cloud-based AI software to help cement plants optimise fuel use and fuel-mix variability. This allows plants to use lower-carbon fuels and deliver real world emissions reductions of 5%.

This is the equivalent to saving 30,000 tonnes of CO2 annually for a typical 2Mt/year plant. As Carbon Re works alongside more plants, the annual carbon savings will ramp up, making a sizeable dent in the cement industry’s carbon footprint over time.

Innovate UK’s grant support through the Transforming Foundation Industries programme gave us the freedom to explore how our AI technology could be applied beyond cement, into glass and steel. With access to data from Glass Futures, we were able to develop a prototype for glass manufacturing – proving that our approach to improving energy efficiency is transferable across foundation industries. This de-risks our expansion into adjacent sectors, strengthens our commercial proposition, and significantly increases the potential climate impact of Carbon Re.

— Buffy Price, Co-founder & COO, Carbon Re

Taking the heat out of cement – in practice

Carbon Re is working with Heidelberg Materials, one of the world’s largest building materials companies, to put our solution to work at their cement plants.

Heidelberg Materials is committed to achieving carbon neutrality, and in 2024, Carbon Re’s AI platform was deployed at the Mokra plant in Czechia with the aim of cutting fuel costs, lowering emissions and improving the quality of the clinker.

The results speak for themselves: in just the initial one-month-on, one-month-off evaluation, their AI platform helped deliver a 4.1% cut in fuel costs, all thanks to a 2.2% reduction in specific heat consumption. Falling heat consumption allowed the Mokra plan team to adjust fuel mixes for the kiln, reducing reliance on costly and carbon-intensive ones like heavy fuel oil towards cheaper alternative fuel sources like refuse-derived fuel.

Not only did the AI platform cut the Mokra plant’s reliance on more costly fuels, but kiln stability was improved. Through using our AI solution’s clinker quality soft sensors, the Mokra plant was able to reduce standard deviations of two key quality indicators, free lime and alite, by 33%. Consistent quality means the plant spends less time and saves on electricity costs when grinding the clinker into cement.

With Carbon Re, Heidelberg Materials was able to cut its fuel costs, produce cement more sustainably and it ended up with a higher-quality end product.

Creating order from chaos

AI is undergoing rapid evolution at present, and one of the best things about AI models is their ability to take stock of ever-changing situations and adapt accordingly. Moving forward, we foresee multiple additional uses for AI capabilities in the cement production process.

As well as helping cement producers increase the alternative fuels to power kiln operations, helping reduce carbon footprints, AI could play a role in helping optimise the quality of the alternative fuels. This could mean sifting the waste to ensure it can be incinerated for fuel to deliver more efficient kilns while keeping fuel costs low for producers.

Ready for the future

We want cement of the future to be resilient and long-lasting, while also produced with minimal environmental impacts. While the UK cement sector has a relatively small carbon footprint, the global cement industry is responsible for 8% of global emissions. To put this into perspective, that’s a greater impact on the planet than deforestation, global shipping and aviation activity combined. As global cement production is forecast to grow by 45% by 2050, if there was a time to start embedding the decarbonisation of cement production, now is the time.

AI has a significant part to play in ensuring that happens – not just in cement – and that’s why Carbon Re is a member of the Industrial Decarbonisation AI Coalition (IDAIC), alongside Innovate UK Business Connect, IDRIC and a number of other important inaugural stakeholders within the foundation industries.

The UK is a thriving hub of innovation when it comes to AI, and IDAIC intends to ensure businesses benefit through increased R&D collaboration to develop more AI tools to aid industrial decarbonisation. To learn more about IDAIC’s work, click here.

Related content

Foundation Industries

Situated in our industrial heartlands, these sectors include metals, ceramics, glass, chemicals, paper and cement, producing 28m tonnes of material per year, and are worth £52bn annually to the UK economy.

AI

Robotics and Artificial Intelligence are significant globalised technologies applicable to every sector. The UK’s extensive industrial and academic research base has immense potential to impact on home and global markets.

Materials

The Materials Team at Innovate UK Business Connect covers a broad scope of the materials life cycle, from feedstock, processing techniques, design and manufacture, testing, standardisation, resource efficiency and circularity.