Driving a circular future: the Longer in use and reuse sprint at Innovate UK Business Connect

UK manufacturing will minimise materials use and waste, practice complete traceability, and use new remanufacturing services. This article explores the vision for Longer in use and reuse (LURU) as informed by engagement with the community throughout 2024.

The vision for Longer in use and reuse (LURU)

The Innovate UK materials and manufacturing vision 2050 is a reimagination of the role that UK materials and manufacturing should have within our economy and society in a strongly net zero focused world.

The vision highlights Longer in use and reuse (LURU) as one of the five core areas of focus for the UK to become a recognised destination of choice for advanced low-carbon manufacturing.

The initiative explored how UK industries can extend product lifetimes and promote reuse to minimise material waste. LURU sprint activities – including desktop research to assess the landscape, a targeted survey to understand business challenges and opportunities, as well as workshops and interviews with selected businesses – gathered insights that identified key challenges, opportunities, and strategies for achieving a circular economy, along with ways to support businesses in the future.

Consumer behaviour and business challenges

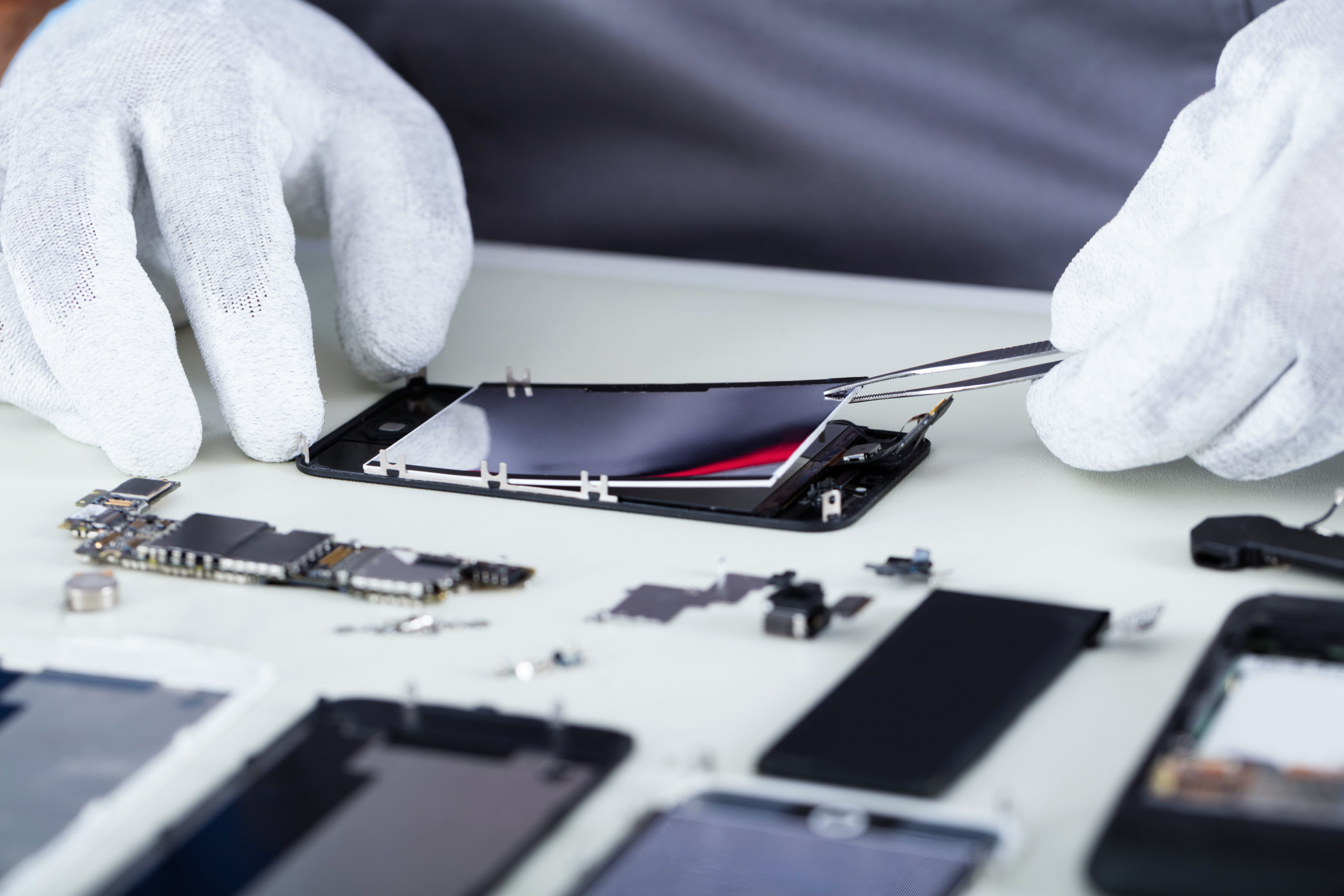

Key findings showed that while ‘reuse’ and ‘longer’ product lifetimes are gaining traction, only 5% of the businesses we interact with are active in this space. Consumer habits, high repair costs, lack of supportive policies, and infrastructure limitations remain key barriers. However, companies across diverse sectors including fashion, electronics, automotive, and construction are pioneering innovative models that prioritise product longevity.

Our focused survey data revealed that, while UK consumers express support for reuse, challenges such as convenience, cost, accessibility, and awareness hinder adoption. Reuse should be valued alongside recycling, yet many businesses struggle to integrate sustainable models profitably. Successful examples like Patagonia’s Worn Wear programme and IKEA’s buy-back initiatives highlight best practices in circular design and Innovate funded innovations from Rype Furniture and Autocraft Drivetrain Solutions are showing UK business appetite for reuse is growing. In addition several other start-up businesses including Tech-Takeback were given the opportunity to exhibit at our Materials Research Exchange 2024.

Our largest workshop was held in London and nearly 100 companies were represented. The recordings are available to watch online: REforMM: Longer in use and reuse workshop.

Adoption and implementation

The outcomes from our combined activities indicate that a shift towards service-based business models (such as leasing and product-as-a-service) could accelerate adoption. However, financial incentives, standardisation, and policy interventions are needed to drive wider implementation. Indeed, to scale LURU initiatives and make repair and reuse mainstream, next steps for businesses and the wider community should be to:

- enhance consumer awareness and incentivise reuse behaviours

- develop standardised frameworks for repair, refurbishment, and remanufacturing

- encourage cross-sector collaboration to optimise material exchange and lifecycle tracking

- invest in reverse logistics infrastructure to facilitate product take-back and redistribution

- implement financial incentives to support businesses transitioning to circular models

Our most recent activity has been to look at the role of Repair Cafes in making reuse mainstream. Our findings are clear that having accessible and more timely access to repair skills would facilitate consumers thinking of repair first, rather than buying a new replacement. A trial of a voucher scheme by the Restart Project to assess the uptake of this is launching in April in London Boroughs.

Final thoughts

The LURU initiative demonstrates that the UK has the potential to lead in sustainable manufacturing and for meaningful change, a concerted effort is needed from businesses, policymakers, and consumers alike.

Thank you to everyone who contributed to the workshops and interviews to inform this Sprint activity. The insights gathered are already being used to help inform the next iteration of the Materials and Manufacturing Vision 2050 and future community building and funding activities. If you are interested in this area and want to know more, then please reach out to sally.beken@iukbc.org.uk.

Related programme

Resource Efficiency for Materials and Manufacturing (REforMM)

The programme aims for the UK to be a leader in resource efficiency with organisations understanding the environmental, social and economic impact of the full lifecycle and thriving from adoption of resource efficient solutions which are fundamental to UK and global Net Zero ambitions.