The Smart design sprint at Innovate UK Business Connect

Effective design methods, design for resource efficiency, and design for maximum through-life value will be at the heart of UK manufacturing. This article is informed by extensive engagement with the community through a series of workshops in late 2024 and explores the vision for Smart design along with the opportunities for the UK.

The vision for Smart design

The Innovate UK materials and manufacturing vision 2050 is a reimagination of the role that UK materials and manufacturing should have within our economy and society in a strongly net zero focused world.

The vision highlights Smart design as one of the five core areas of focus for the UK to become a recognised destination of choice for advanced low-carbon manufacturing.

The outputs were intended to:

- build detailed understanding of UK strengths and opportunities

- increase knowledge of weaknesses, threats, and barriers to sustainable growth

- identify priorities for innovation intervention

- provide feedback for refinement of the 2050 Vision

Understanding the UK’s strengths and opportunities

The Smart Design core area was divided into three innovation strands for which there were three individual workshops:

- Designing the right things

- State-of-the-art design tools

- New ideas de-risked fast

Across all three online workshops, 237 participants from across industry, RTOs and academia attended and contributed.

Strengths

Strengths were identified in:

- Standards: Well established regulations and standards, with UK stature and respect internationally in this area at International Organization for Standardization (ISO) and British Standards Institution (BSI).

- Infrastructure: Centres of excellence – e.g. Catapult Centres, Turing Institute, Science and Technology Facilities Council (STFC), Isambard-AI, and access to computational power. A research and business capability in simulation tools. A prototyping supplier network as well as world class demonstration in high value complex engineering systems such as in the aerospace sector.

- Skills: A strong interlinked university network offering undergraduate and post graduate degrees in Design Engineering and Design for Manufacture with simulation tools readily available for students.

Opportunities

Opportunities were identified in:

- Design Tools: Materials software to support design, manufacture, and sustainability. Developing open-source platforms to enable easier integration with existing Commercial Off-The-Shelf (COTS) software.

- Standards: Increase accessibility by to standards, especially for SMEs. An opportunity to influence on a global scale through ISO. Definition of a standards framework that would enable interoperability of data across multiple platforms/software. To be a world leader in high value product development and certification – with proportionate and agile regulatory practices. Agreed ontology (or suitable translations) to help share information and data across different sectors and domains. Regulatory innovation encompassing digital technologies. Changing design codes to consider need for climate resilience.

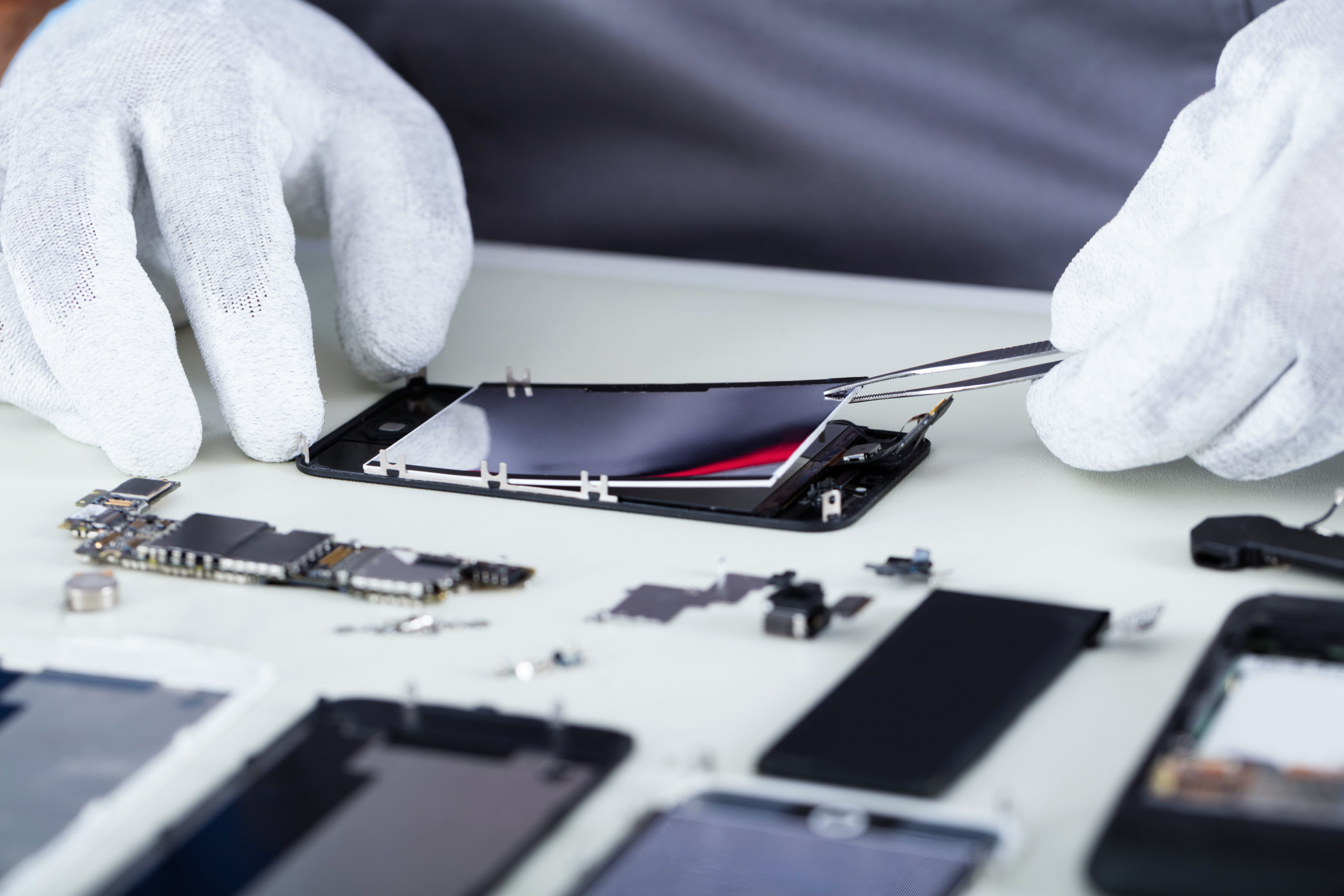

- Sustainability: Designing for the entire life cycle of products. Develop reliable baseline sustainability data. Design for disassembly and multiple lives – UK to become global remanufacturing workshop to improve current life or repurpose for multiple lives. Design for circularity. UK Leadership in sustainable design, manufacture and through life engineering. Design for automated disassembly and recycling.

- Infrastructure: National assets e.g. materials/manufacturing database, open source and accessible platforms for federated design and engineering. Support on how to implement the Verification and Validation framework through R&D processes. Coordinated framework for IP sharing across the network (simplify exchange and collaboration). Mentors to guide through opportunities, hardware, software, data, potential collaborations, partners, etc.

Priority areas for innovation intervention

The outcomes from the workshops identified potential areas for innovation intervention to move things forward:

- Skills: Training for SMEs and engagement with academia to produce graduates with more relevant skills

- Design Tools: Encouraging Tier 1, Tier 2 etc suppliers to accept outputs of newer software / newer file types. Visibility of next generation tools – where can they make the greatest impact (via case studies or similar). Design for Manufacture and Design for Automation.

- Funding: Easy to access small grants that allow for “fail fast” projects. Calls for innovation around particular problems. Create opportunities for first of a kind, funded demonstration projects for SMEs.

- Networks: Establish UK-wide Engineering/ design/ manufacturing digital hub enabling IP considerate collaboration and networking. Continuous landscape mapping (collaboration between industry and academia) – to influence the planning and investment.

- Sustainability: Support design for circularity (training, initiatives, funding) led by funding councils and driven by UK Government.

- Standards: Improved accessibility to standards. Create cross sector standards. Institutions to lead on revising design codes and training requirements to increase climate resilience.

- Infrastructure: Establish the back-bone national infrastructure for collaboration (network, computing, access), a central facilities network for laboratories and access to all software.

Conclusions

Key conclusions from the Smart design sprint activity:

- There have been some opportunities identified around SME support and Design making a bigger impact on the sustainability agenda.

- Participants at the workshops would like government funding in this area revisited, with the aim of increasing the support needed.

- The UK has a strengths and a good international reputation in many aspects of standards, these need to be made more available, especially to SMEs.

- The High Value Manufacturing Catapult has convened a Smart Design Innovation Network. Discussions about future collaborations should continue.

Thank you to everyone who contributed to the workshops to inform this sprint activity. The insights gathered are already being used to help inform the next iteration of the Materials and Manufacturing Vision 2050 and will be used to help inform future community building and funding activities. If you are interested in this area and want to know more, then please reach out to ajay.kapadia@iukbc.org.uk.

Related programme

Resource Efficiency for Materials and Manufacturing (REforMM)

The programme aims for the UK to be a leader in resource efficiency with organisations understanding the environmental, social and economic impact of the full lifecycle and thriving from adoption of resource efficient solutions which are fundamental to UK and global Net Zero ambitions.