Modular Chemical Robot Farms for Chemistry

Chemify, backed by £7.5m from the Innovation Accelerator, is pioneering on-demand chemical synthesis using chemputation technology. It’s scaling up in Glasgow, aiming to revolutionise chemical production for pharmaceuticals, materials, agriculture, and green energy.

Project

Modular Chemical Robot Farms for Chemistry

University

University of Glasgow

Lead Organisation

Chemify

Location

Scotland

Funding

£7.5m

Project Overview

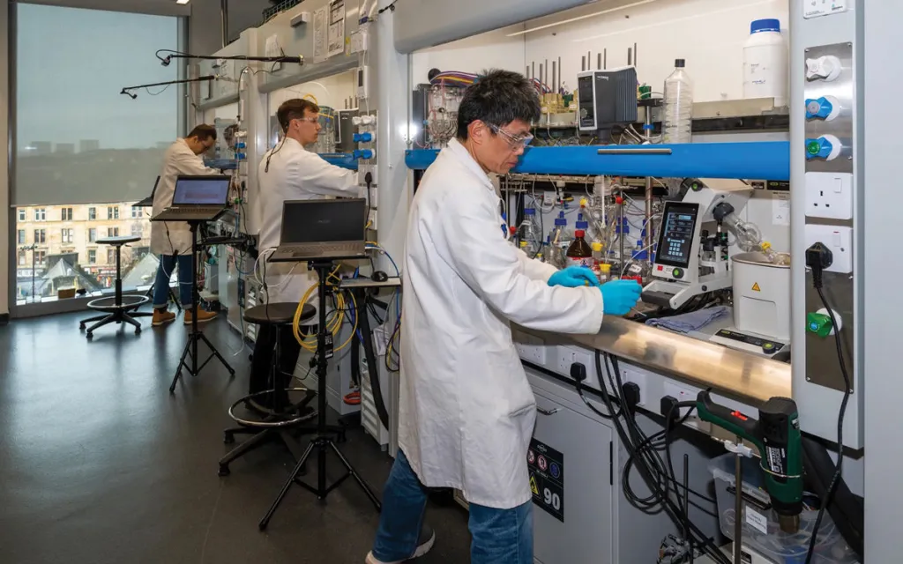

Through £7.5m of funding from the Innovation Accelerator programme, University of Glasgow spin-out Chemify has developed a new era of chemical production through its innovative chemputation technology.

With a growing team of over 120 employees, Chemify is focused on developing automated systems that can synthesise chemicals on demand, controlled entirely by computer algorithms.

Chemify is aiming to scale-up operations to construct a Glasgow based prototype pilot plant, employing over 100 people. This facility will serve as a precursor to a massive ‘chemical giga factory’, capable of producing trillions of unique chemicals on demand for applications ranging from pharmaceuticals and high-value materials to agriculture and green energy.

Chemify’s approach involves digitising chemical processes and developing cutting-edge automation hardware. By integrating these technologies, the company aims to create a scalable, efficient, and cost-effective solution for on-demand chemical synthesis.