Loughborough-based R3V Tech has developed a breakthrough process that transforms crude glycerol waste from biodiesel production into solketal, a high-value green solvent, increasing its market value by up to 50 times. Supported by Innovate UK ICURe, the scalable technology also captures carbon dioxide, creating both environmental and commercial benefits.

From lab discovery to industry challenge

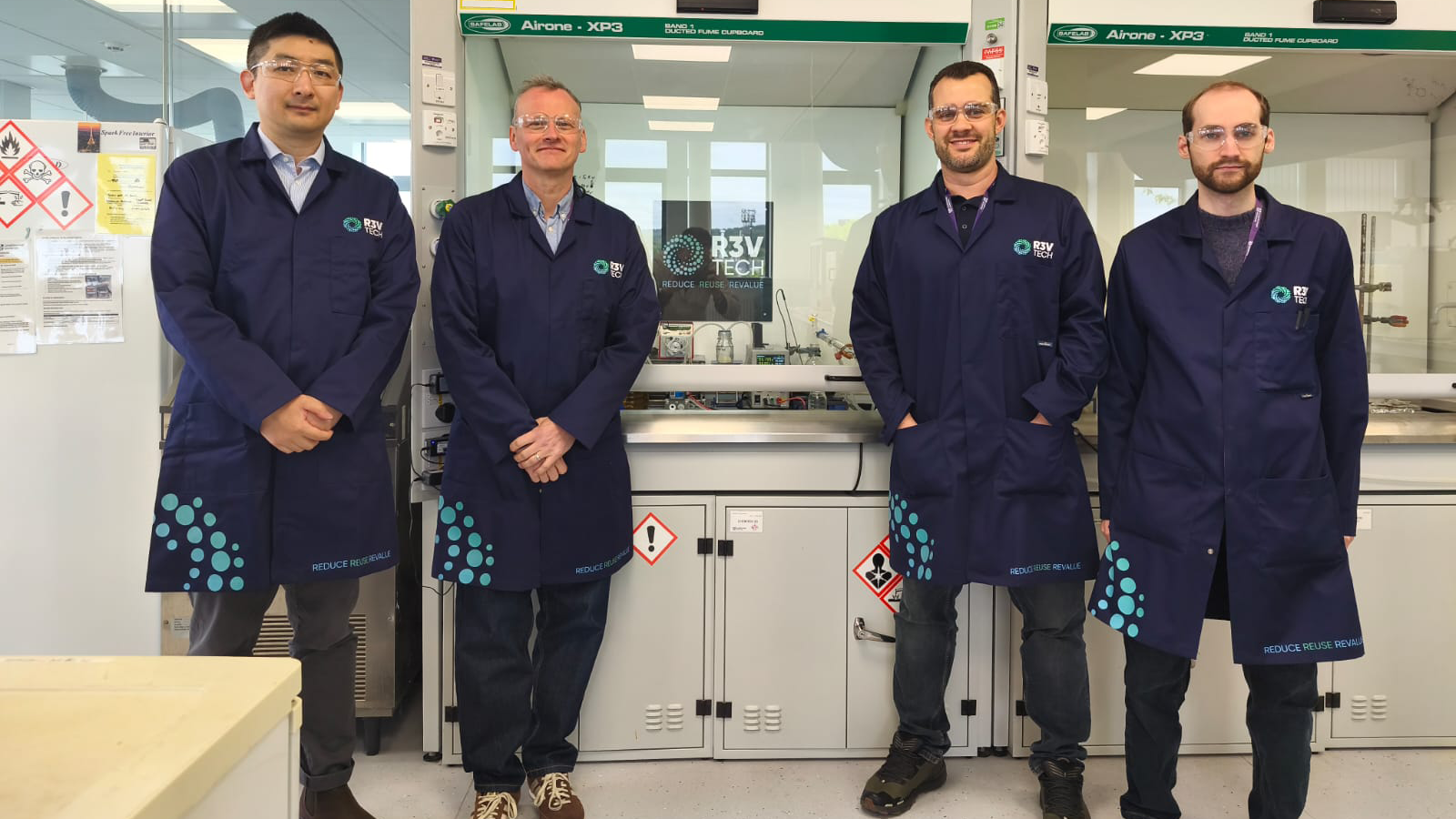

R3V Tech’s journey began at Loughborough University, where Dr Adriano Randi and Professors Jin Xuan and Benjamin Buckley discovered an electrochemical pathway to convert crude glycerol into solketal.

Biodiesel producers generate vast quantities of crude glycerol, often sold cheaply or shipped long distances for refining which is both costly and carbon intensive. With prices as low as £0.10/kg, the market is oversupplied, leaving producers searching for new solutions.

A drop-in solution with global potential

R3V Tech’s modular manufacture-in-a-container system allows biodiesel plants to process waste glycerol on-site, avoiding transport costs and opening access to a billion-pound market for green solvents.

The process uses crude glycerol directly, operates at room temperature and atmospheric pressure, and incorporates waste carbon dioxide, making it safer, cheaper and more sustainable than traditional methods.

ICURe’s Role in the breakthrough

Through the ICURe Discover, Explore and Exploit pathways, Dr Randi engaged directly with potential customers, challenging early assumptions and confirming biodiesel producers as the prime market.

At the outset, commercialisation was uncertain. Industry interest was high, but customers wanted proof that the technology could scale, operate with high energy efficiency and consistently deliver quality product. ICURe’s market validation process, expert mentoring and structured engagement with industry partners provided the evidence base and confidence needed to move forward.

Results so far

Since taking part in ICURe, R3V Tech has secured a £75,000 Royal Academy of Engineering Fellowship and a £300,000 Innovate UK grant, signed an exclusive licence for the protected process from Loughborough University, and formally spun out in December 2024. The team has also engaged with three major biodiesel plants and partnered with Shell’s Startup Engine and Royal Society of Chemistry through Change Makers to accelerate development.

Next steps

The team is still scaling from 1 g/h to 1 kg/h production, with a £700,000 raise planned to reach 20 kg/h for a pilot demo.

ICURe was key to defining the future of R3V Tech. It helped me understand the market, customer pain points and needs. Through ICURe, I gained enough traction and letters of commitment to open doors and move our project forward.

– Dr Adriano Randi, Entrepreneurial Lead, R3V Tech Ltd

R3V Tech shows how Innovate UK ICURe helps university research tackle industry challenges while delivering environmental and commercial impact – in this case, turning biodiesel waste into valuable, sustainable products.