Resource Efficiency for Materials and Manufacturing (REforMM)

The programme aims for the UK to be a leader in resource efficiency with organisations understanding the environmental, social and economic impact of the full lifecycle and thriving from adoption of resource efficient solutions which are fundamental to UK and global Net Zero ambitions.

About the programme

Part of Innovate UK’s focus on net zero is the £15m Resource Efficiency for Materials and Manufacturing (REforMM) programme. This includes the delivery of a number of ‘Sprint’ activities which aim to build a community of engaged people around a particular topic to debate barriers, challenges and identify key opportunities in moving towards increased resource efficiency.

REforMM is one of two programmes delivered under the Reimagining Materials and Manufacturing together banner and is designed to put in place the key building blocks to help businesses transform to a resource efficient future. It is informed by Innovate UK’s 2050 vision document which delves into the challenges and opportunities that lie in front of UK materials and manufacturing sectors as we transition to a sustainable, resilient and technologically advanced industry.

The Sprint activities align with key areas of focus in the vision, namely:

- Materials for the future economy

- Smart design

- Resilient supply chains

- World-class production

- Longer in use and reuse

This programme aims for:

- The UK to lead in resource efficiency

- UK organisations to understand the environmental, social and economic impact of the full product lifecycle

- UK organisations to thrive from the development and adoption of resource efficient solutions which are fundamental to UK and global net zero ambitions

Core focus areas of the programme

FOCUS AREA

Materials for the future economy

New material applications for cutting-edge products that reduce emissions, energy consumption and costs.

FOCUS AREA

Smart design

Effective design methods, design for resource efficiency, and design for maximum through-life value.

FOCUS AREA

Resilient supply chains

Sustainable feedstocks, supply chain visibility, and co-location of waste and emission streams.

FOCUS AREA

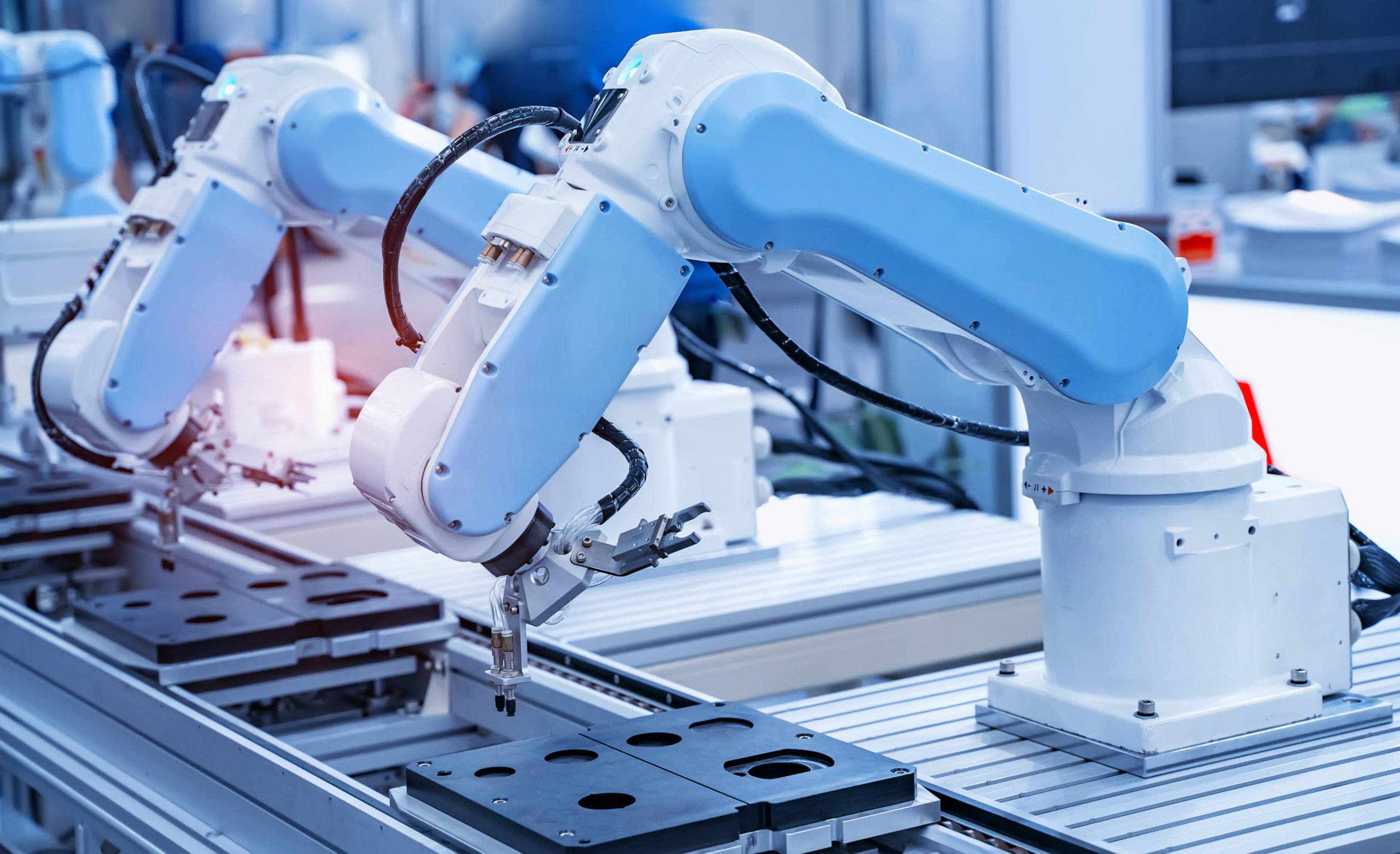

World-class production

Flexible production capacity, minimal material waste, high-quality products, high productivity, and full adaptivity.

FOCUS AREA

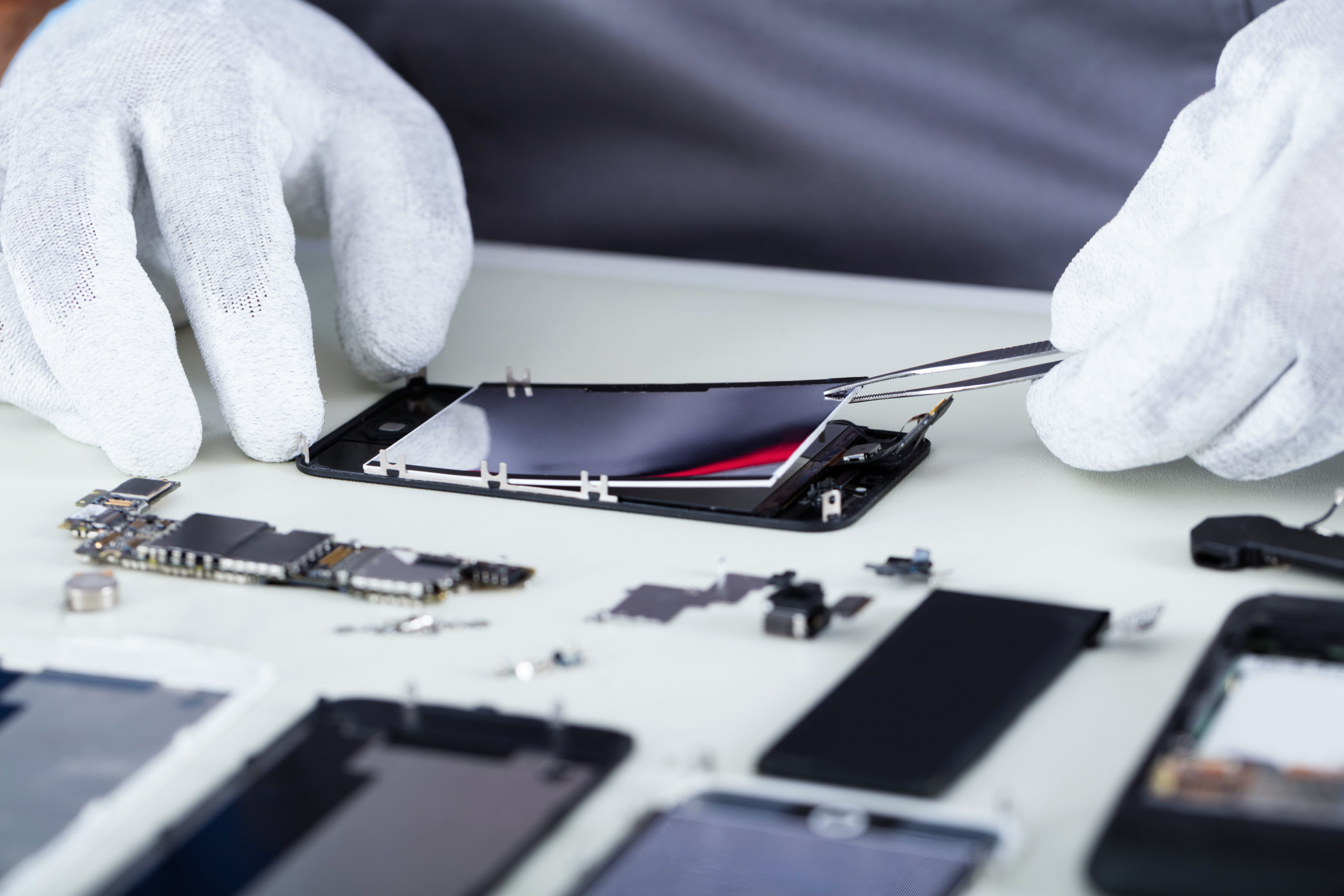

Longer in use and reuse

Minimising materials use and waste, practising complete traceability, and using new remanufacturing services.

PERSPECTIVES

Key insights from the core focus areas

The Resource Efficiency for Materials and Manufacturing (REforMM) programme has successfully delivered five sprints, generating valuable insights that assist businesses in transitioning towards a resource-efficient future. Explore the outputs from these sprint activities, which provide a comprehensive understanding of the UK's strengths and opportunities in each focus area, as well as the identified priorities for future innovation interventions.

Discover insights

Weffan: Weaving Sustainability into Fashion

Learn how a Resource Efficiency for Materials and Manufacturing (REforMM) feasibility study enabled Weffan to investigate the optimisation of machinery, forge crucial UK partnerships, and develop a business case for 3D woven garments.

Learn more

Amphico: Scaling up sustainable materials and manufacturing

What began as a bold scientific idea has grown into Amphico, a cutting-edge material science startup based in London, dedicated to reshaping the textile industry. With a team spanning science, design, and engineering, Amphico is developing PFAS-free, mono-material textiles that are not only waterproof and breathable, but also fully recyclable. Central to this mission is the use of machine learning to solve one of sustainable fashion’s biggest challenges: achieving vibrant, customisable colours while drastically reducing water use and carbon emissions. This breakthrough would not have been possible without the support of Innovate UK’s REforMM programme, which has played a vital role in accelerating Amphico’s journey from concept to scalable innovation.

Valuechain: AI Supply Chain Solution Crosses Industry Boundaries

Learn how a Resource Efficiency for Materials and Manufacturing (REforMM) feasibility study enabled Valuechain to partner with industry experts and develop an AI-first approach to mapping potential supply chain routes.

Learn more

Our Experts

Related Opportunities

Advanced manufacturing supply chain innovation: feasibility studies

Opens: 02/02/2026 Closes: 11/03/2026

Up to £100k per project for feasibility studies to make supply chains more resource efficient and resilient through addressing cross cutting challenges.

More Information

Knowledge Transfer Partnership (KTP): 2026 – 2027 Round 1

Opens: 02/02/2026 Closes: 01/04/2026

UK registered academic institutions, RTOs or Catapults can apply for a share of up to £10 million to fund innovation projects with businesses.

More Information

Innovate UK Innovation Loans Round 25

Opens: 08/01/2026 Closes: 04/03/2026

UK registered businesses can apply for loans for close to market innovative projects with strong commercial potential. They must significantly improve the UK economy and drive societal benefit.

More Information

Related Events and Recordings

Related Perspectives

Related programme

Sustainable bio-based Materials and Manufacture (SusBioMM)

The sustainable bio-based materials and manufacture (SusBioMM) programme seeks to address the challenge of developing innovations in sustainable and scalable biomanufacturing processes.

Manufacturing Vision 2050

The design of the funding programme has been informed by Innovate UK's Manufacturing Vision for 2050. The document is a re-imagination of materials and manufacturing together, delving into the challenges and opportunities that lie in front of the UK materials and manufacturing sectors over the next 30 years. With more than 170 recent references analysed and more than 120 stakeholders consulted, this is one of the most comprehensive studies of its kind. Click here to read more.